Tests of a lawnmower retrofitted with

the Multi-Fuels Processor (PMC)

All informations and diagrams are published freely (freeware) and are intended for a private use and a noncommercial use

Created on 10-22-00 - JLN Labs - Updated on 10-25-05

Tests of a lawnmower retrofitted with

the Multi-Fuels Processor (PMC)

All

informations and diagrams are published freely (freeware) and are

intended for a private use and a noncommercial use

Created on

10-22-00 - JLN Labs - Updated on 10-25-05

![]() Cliquez

ici pour la version Française

Cliquez

ici pour la version Française ![]()

The Multi-Fuels Processor of GEET is a new

internationally patented technology (US005794601A1) whose

inventor is Paul Pantone. This revolutionary system allows the

common 4 strokes engines to run with a water/hydrocarbure

mixture. It is able to use all types of fuels (gasoline, diesel,

kerosene, crude oils and others derived from hydrocarbons...)

with its endothermic plasma reactor.

The Multi-Fuels Processor allows also a significant reduction of pollution

generated by the gaz exhaust of almost 85% compared to a

conventional engine.

Tests carried out by many industrialists and experimenters

already showed that it is even possible to make function an

engine equipped with this device with a mixture of hydrocarbons (20%) and water

(80%)...

The device is composed of three principal parts:

The conventional carburettor and the muffler (and its catalytic system) are not necessary any more after installation of the device.

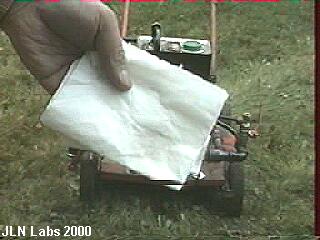

Tests by J-L Naudin of a retroffited lawn mower with the GEET Multi-Fuels Processor

October 21 2000, I was pleased to test myself and this for the first time, a lawn mower been driven by a 4 strokes engine retrofitted with the Multi-Fuels Processor invented by Paul Pantone. All the parts used are standard and come from stores of do-it-yourself and/or hypermarkets ( plumbing departement ). The parts were selected to be more closer to the original plan published freely by Pantone on the Internet network the 11-11-99. You will find at the bottom of this page, the diagram of my current setup under tests which gives me whole satisfaction. The bubbler is a simple metal can of 5 liters. The assembly of the unit was carried out so that the machine can be used in real conditions of use (shearing of grass).

Description and basic principles of the endothermic plasma reactor (by Jean-Louis Naudin) :

The heart of the Multi-Fuels Processor of GEET is a self-inducing plasma generator or a plasma reactor with endothermic reaction.

The endothermic reactor is composed of two coaxial

steel cylinders:

- the interior cylinder (threaded at each end), called the

pyrolytic chamber (430mm length and 15mm of inner diameter)

contains a steel rod of 300mm length and 13mm of diameter (not

magnetized before the burning-in). A side of this steel rod is

round in order to identify its magnetic polarity after its

disassembling. The rod is maintained in the center of the

pyrolytic chamber with to 3 small nipples welded at each end.

- the external cylinder (threaded at each end) is a steel tube of

300mm length and 26mm of inner diameter.

The two cylinders are placed coaxialy with two reducing T (showed

on the diagram below) placed at each end.

The bubbler is a tank containing a mixture of water and hydrocabures (gasoline, diesel, kerosene, crude oils and others derived from hydrocarbons...).

The hot gas flow coming from the exhaust of the engine circulates by the outside part of the reactor with a strong kinetic energy, that contributes to bring up to very high temperature the steel rod (being used as heat accumulator) contained in the pyrolytic chamber. The gases cross the engine and penetrate then in the bubbler containing the water/hydrocarbures mixture. The vapor of the mixture is strongly aspired by the vacuum created by the engine intake and is pushed by the pressure coming from the exhaust. The kinetic energy of the vapor is increased considerably by the reduction of the diameter in the pyrolytic chamber (by Venturi effect). The combined effect of the high temperature and the increase of the kinetic energy produces a thermochemical decomposition ( molecular breakdown ) of the water/hydrocarbures mixture.

The endothermic reactor forms an Electro-Plasma-Chemical unit (EPC) and it is now possible to create a high-output fuel coming from the decomposition of the water contained in the water/hydrocarbures mixture. This fact is confirmed by the presence of oxygen gaz (O2) in great amount measured in the exhaust.

A close view of the Intake/Exhaust

connection of the engine

One break-in period of at

least 20 minutes with pure gasoline ( 95LL ) is necessary. The

mower was placed so that the axis of the endothermic engine (2)

is aligned with the North-South terrestrial magnetic axis. The

hot side of the reactor chamber (engine exhaust) is placed

towards the North, and this in accordance with the

recommendations of Paul Pantone. After this break-in period, the

tests of the mower started.

A first successful test was carried out with pure gasoline 95LL,

then a second test successful with a mixture of water 50% and

gasoline 50%.

A test more

surprising were carried out

with 75%

of WATER and 25% of gasoline (95 LL) :

the retrofitted lawn mower runs very well in real condition of

use...

Starting is done without problem (like a normal mower) with simply a small fuel injection at the input of the admission valve (5) before launching. It is necessary to wait approximately 1 minute so that the engine reaches its optimal operating temperature (approximately 800° C). After this period of temperature setting, the engine of the mower is able to run at full speed. The max turn speed is obtained with the adjustments of the valves 3, 4, 5.

The exhaust gas are very clean and not very odorous.

On 10-22-00, I fully confirm that this lawn mower retroffited with the GEET Multi-Fuel Processor is able to run very well with 75% of water and 25% of gasoline.

Additional comments : The main real interesting fact in the GEET Muti-Fuels processor is that this device is able to use any kind of hydrocarbures like crude oils, methanol, gasoline, various solvents, kerozen, bio-diesel mixed with water.... I have just started my retrofitted lawn mower test phase, more tests will be soon conducted about its efficiency. Today, I can only say that the GEET Fuel processor works VERY WELL on my own retrofitted lawn mower according to the original Pantone diagram and observations :

This device is not a water engine, this device is a 4 stroke engine ( a LAV35 Tecumseh, 3.5HP ) which runs with its own multi-fuels miniature refinery on board... Very usefull for anyone those want to use any sources of hydrocarbures....... |

Below some videos of the tests :

You must

have installed the application " RealPlayer Video ",

freely downloadable with ![]()

Click on a picture to see the corresponding video.

The first turns (burning-in of 20mn) of the

retrofitted engine with the Multi-Fuel Processor

Video of the TEST with

75% of WATER and 25% of gasoline...

![]() Vidéos de

démonstration de la tondeuse PMC en Haute Qualité

Vidéos de

démonstration de la tondeuse PMC en Haute Qualité

![]() High

Quality videos about the PMC retrofited lawnmower

High

Quality videos about the PMC retrofited lawnmower

If you wish to check this fact by yourself, you will find below the real diagram used with my retrofitted lawn mower.

All information and diagrams are published freely (freeware) and are intended for a private use and a non commercial use.

I point out that all the tests must be carried out in the open air and in a wide place and by people qualified to handle the machine being used for the tests. This is an experiment and I decline any responsibility on the possible damage caused during your tests. This being carried out under your whole responsibility.

Click on the diagram

above to enlarge

Click here to download the full PMC diagram ( in Adobe Acrobat PDF format )

A test feedback about the Fuel consumption ( 10-28-00 )

The Paul Pantone Fuel processor has been patented worldwide :

Other similar patents which use the same technology :

Interesting documents :

Plasmatron (document source : http://www.bellona.no/en/energy/report_3-1999/11197.html )At the Massachusetts Institute of Technology (MIT), researchers are developing a reformer, which, like the KCB&H one, uses plasma for reforming hydrocarbons. The advantage of a plasma reformer is that it can use all forms of hydrocarbons, including heavy oil fractions. In addition, the plasma reforming can operate in pyrolytic mode (thermal degrading of organic material without air or oxygen) so that the carbon is turned into soot. This eliminates the formation of CO2. Plasma technology allows for a more compact and lighter design than traditional reformers because the reaction occurs much faster. MIT is studying use of the plasma reformer in the

pyrolytic, partial oxidation and steam reforming methods

mode. MIT's "Plasmatron" operates at

temperatures of over 2,000 oC, and the amount

of hydrogen produced is around 80-90%. The main

disadvantage with plasma reforming is its dependency on

electrical power. MIT hopes to lower the need for

electricity to 5% of the fuel's combustibility caloric

value through heat recycling and a better reactor design;

today it is 20%. |